A Made in France production

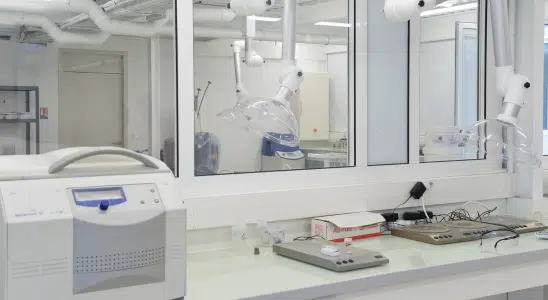

All our LuminoKrom® photoluminescent paints are produced at our Pessac industrial site in France according to rigorous manufacturing processes and under the continuous supervision of our production control laboratory.

This 100% French know-how guarantees optimum quality at every stage, from development to delivery. Thanks to a team of experts and state-of-the-art equipment, we can guarantee the traceability and conformity of our products to the strictest standards.

By favoring Made in France production, we support French industry while reducing the environmental impact of projects taking place in France, particularly in terms of transport and carbon footprint.

- Industrial site in Pessac: In 2018, OliKrom is setting up a production site of over 1,600 m2, with an investment of over 5 million euros.

- Production capacity: OliKrom adapts to demand with mixing reactors ranging in capacity from 50 L to over 1000 L.

- Quality approach: OliKrom follows strict production control processes, guaranteeing ISO 17398-compliant products. This ensures luminance levels (class G) that provide 10 hours of visibility in the dark.

- Delivery times: The average delivery time for LuminoKrom® paint is 7 working days.

- Customer relations: OliKrom focuses on understanding the needs of its customers (local authorities, manufacturers, applicators) in order to provide services tailored to each stage of the project.

Large-scale modular production

In 2018, OliKrom invested over 5 Million Euros in modern industrial infrastructure in order to produce on a large scale while retaining flexibility for specific projects.

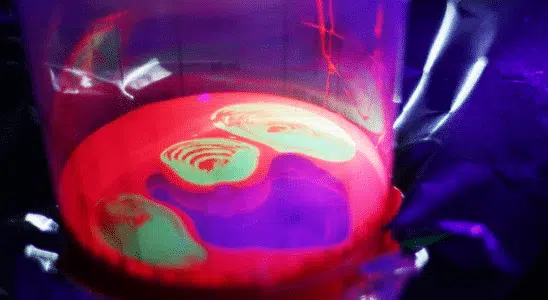

The LuminoKrom® range is now being mass-produced, notably for road signage applications. This range benefits from optimized processes enabling the production of large quantities of photoluminescent coatings used for safety in public infrastructures, such as road markings on bicycle paths and sidewalks.

Customized, adaptable production

OliKrom offers tailor-made solutions, and the production process is scalable to meet specific orders. This includes the ability to adjust formulations for a variety of applications (aerospace, road safety, automotive, etc.), producing both small and large volumes according to customer requirements. It also enables us to respond rapidly to requests while minimizing waste and energy consumption, with a view to sustainability.

Future expansion of our production site

With growing demand for their innovative solutions, OliKrom has announced a tripling of the surface area of its production plant. The modular approach and constant investment in R&D and process optimization mean that the plant can scale up without compromising product quality. In the coming months, the company will expand its current production site with the acquisition of the adjacent 4,500 m2 plot.

OliKrom's quality approach

OliKrom's quality approach is based on several fundamental pillars to guarantee the performance and reliability of its intelligent pigments and innovative solutions such as LuminoKrom®. This integrated quality approach enables OliKrom to position itself as a leader in the field of intelligent materials, while offering reliable, sustainable and environmentally-friendly solutions. OliKrom ensures that its products comply with international standards and regulations. This includes quality certifications such as :

ISO 9001

OliKrom has implemented an ISO 9001-compliant Quality Management System (QMS) to ensure that every stage of production meets high quality standards, from design to delivery.

Environmental standards

The company incorporates eco-responsible practices into its manufacturing processes, taking care to reduce CO2 emissions and use non-toxic, environmentally-friendly materials.

Rigorous quality control

- Raw material control: Intelligent pigments are produced from carefully selected raw materials. Each batch is tested to ensure that it meets quality criteria before being used in production.

- Production monitoring: OliKrom implements controls throughout the manufacturing process to ensure that pigments such as LuminoKrom® meet technical requirements (durability, chemical stability, weather resistance, photoluminescence, etc.).

- Finished product testing: Prior to delivery, each product undergoes performance testing to ensure compliance with the technical specifications expected by customers. Tests are carried out under real-life conditions to validate durability and effectiveness.

Continuous innovation and R&D

- In-house laboratory: OliKrom has a research laboratory dedicated to the development of new solutions. R&D teams work closely with the quality department to ensure that every innovation meets rigorous safety and performance criteria.

- Prototyping and industrialization: Before bringing a new solution to market, OliKrom goes through prototyping and industrial validation phases to optimize processes and ensure the quality of final products.

Commitment to customers

- Technical support: OliKrom supports its customers with ongoing technical support. This includes advice on coating application, as well as post-installation follow-up to ensure long-term satisfaction.

- Customization: OliKrom adapts to customers' specific needs by offering tailor-made solutions, including adjustments to formulations to meet specific performance and durability criteria.

Compliance with safety regulations

- Non-toxicity: OliKrom products, including photoluminescent pigments like LuminoKrom, are designed to be non-toxic and safe for the environment and human health.

- European regulations: Our products comply with European standards on chemical safety, in particular REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

or questions about our products?